VibroCell

Brief

The sensors and the entire system was designed for remote control of the vibration and temperature of mechanical devices. Sensor, being powered by batteries, have RF link; it is suitable for monitoring of the status of various mechanisms – drives, motors, gearboxes, pulleys, fans. Due to the wireless implementation, the sensor can also be easily installed on rotating elements. In addition to vibrations, the sensor allows you to measure the rotational speed (based on acceleration analysis) temperature Sensor’s operation time without changing the battery is up to 3 years.

Device monitoring

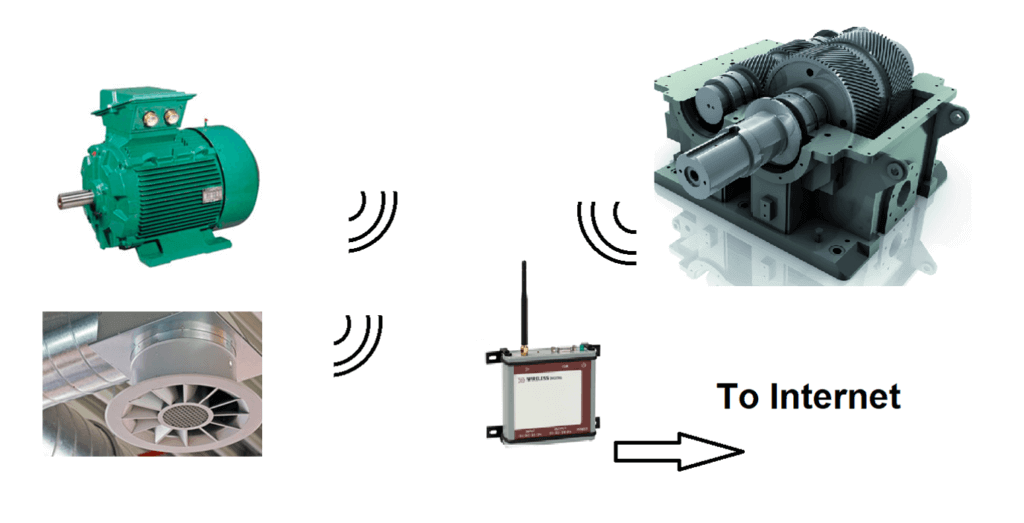

Monitoring System

The minimum functionality of the system consists of a set of sensors and a gateway connected to the Internet. Sensors (about 16 sensors per 1 gateway) collect information about vibrations and transmit to the gateway The gateway performs initial processing, buffering and sending the data further to the data center Engineers can get an access directly to the gateway for data analysis or work with data center Datacenter can be located in the cloud or at the customer’s site.

Parameters

Has dimensions of 70 * 30 * 25 mm

Powered by two AAA batteries

- It can be attached to the surface with two screws

- It has IP56 protection class

Result

VibroCell is a wireless instrument that helps engineers perform dynamic analysis of rotating interaction and develop improved designs for rotating components. It’s available in different packages for a range of applications. In addition, data from this instrument can be used with Technical Guard (another software solution) algorithms that detect and predict faults and issues based on external acoustic signatures. Built for prognostic purposes.

VibroCell delivers great improvement in safety, performance, and mainteznance costs for future generations of rotating components.